10 Best Cnc Wood Milling Machines 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

Most important from

75 reviews

The FoxAlien CNC Router Machine XE-PRO is a versatile milling machine suitable for both wood and aluminum cutting. It features a 400W spindle, providing decent power for various projects. Precision and accuracy are enhanced by the ball screw driven system on the XYZ axes, which minimizes backlash and improves cutting quality.

Additionally, the machine uses dual linear rails on the Z axis, enhancing rigidity and stability during operations. Speed is a notable advantage, with a maximum moving speed of 5000mm/min, making it significantly faster than many other models with open-loop stepper motors. The control system is Grbl-based, which is familiar to many users and supported by numerous online tutorials, making it user-friendly, especially for beginners.

Build quality is strong, leveraging aluminum construction for durability, and it weighs a substantial 84.6 pounds, indicating robustness. The machine’s design is upgradable, allowing users to convert the XY axes to linear rails for industrial-grade performance at home, adding long-term value. This CNC machine is an excellent fit for hobbyists and small-scale professional projects, offering a good balance of speed, precision, and upgradability.

Most important from

75 reviews

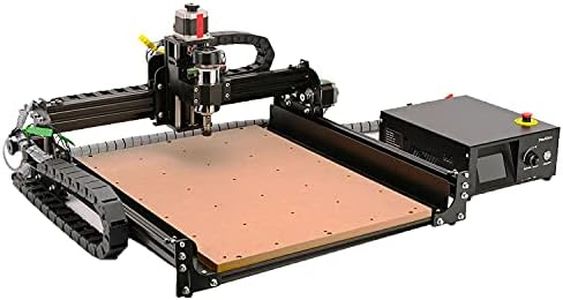

Powermatic PM-2X2R CNC Router Machine with Router Mount (1797022K)

The Powermatic CNC Router Machine (Model PM-2X2R) is a sturdy and reliable choice for wood milling projects. It has a 3 HP spindle, which gives it enough power to handle various wood types smoothly. The machine’s gantry is made from gravity-cast aluminum, offering good stability, which helps improve precision during work. Precision ball screws with recirculating ball bearings allow the machine to move quickly and accurately across all axes, supporting detailed milling jobs. Its working area of 2 feet by 2 feet is suitable for medium-sized projects, making it a good fit for hobbyists or small workshop users.

The control system includes a handheld controller connected by a cable to the DSP control box, allowing easy re-zeroing of the Z-axis with a simple button press, which simplifies setup and adjustments. The flexible nylon track chains help reduce stress and rubbing, increasing durability. Additionally, the MDF spoil board protects the machine’s table and can be resurfaced with a pre-loaded program to keep work surfaces clean and accurate.

The machine weighs 598 pounds, reflecting its solid build with alloy steel and aluminum components, ensuring durability and stability. It runs on standard 115V power, making it easy to use in typical workshop settings. Mobility is aided by integrated casters, while independent leveling feet ensure stable operation. However, the included router mount means you’ll need to supply your own router, which could be an extra expense. Also, with its size and weight, it’s not the easiest to move frequently despite the casters. This CNC router is well suited for users looking for a reliable, precise milling machine with a decent working area and good build quality. It balances speed, accuracy, and durability, but might be less ideal for very large projects or those needing a more advanced or wireless control system.

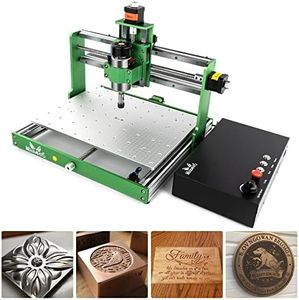

Genmitsu CNC Router Machine 4040-PRO for Metal Acrylic Cutting Milling, GRBL Control, Lead Screw Driven, 3 Axis Engraving, Working Area 15.7” x 15.7” x 3.1”

Most important from

408 reviews

The Genmitsu CNC Router Machine 4040-PRO is designed for woodworking, metal, and acrylic cutting, making it versatile for various DIY and professional applications. Its spindle mounts are adaptable, supporting original spindles, 300W spindles, and laser modules, with additional options available for purchase. This flexibility ensures users can adapt the machine to different projects and materials.

One of the standout features is its stability, attributed to the all-metal frame and dual Y-axis rails, which promise durability and precision. The working area of 15.7” x 15.7” x 3.1” is ample for most woodworking needs, and the redesigned Z-axis makes spindle swapping straightforward, enhancing usability. The upgraded control box and mainboard, equipped with essential functions like emergency stop and home buttons, and driven by a powerful Toshiba TB6S109 driver with a 32-bit chip, offer robust control and ease of maintenance.

Additionally, the support for a 4th axis rotary module and Wi-Fi control module means the machine can handle more complex tasks and be controlled remotely, adding to its versatility. However, at 47.2 pounds, it is relatively heavy, making it less portable. Assembly is user-friendly with pre-assembled main parts, allowing for a quick setup in about 15 minutes. The spoilboard, consisting of two replaceable MDF boards, is practical for maintenance. This product is ideal for hobbyists and small business owners who need a reliable, versatile, and upgradeable CNC machine for a variety of cutting and engraving tasks.

Most important from

408 reviews

Buying Guide for the Best Cnc Wood Milling Machines

Choosing the right CNC wood milling machine can be a game-changer for your woodworking projects. These machines offer precision, efficiency, and the ability to create complex designs with ease. To find the best fit for your needs, it's important to understand the key specifications and how they impact performance. By considering your specific requirements and the features of different models, you can make an informed decision that will enhance your woodworking capabilities.FAQ

Most Popular Categories Right Now