10 Best Commercial Grain Mills 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Wondermill Grain Mill - Electric Grain Mill Grinder for Healthy Gluten-Free Flours

Most important from

1361 reviews

The Wondermill Grain Mill is a robust electric grinder designed for both home and commercial use. It boasts a powerful 1,250-watt motor, enabling it to grind over 100 lbs of flour per hour, making it one of the faster options in its price range. This makes it suitable for high-demand environments like small bakeries or health food stores. The mill uses a micronizing milling chamber with stainless steel fins, which helps preserve the nutrients in the flour by preventing overheating, a crucial feature for those focused on health benefits.

Additionally, it's versatile enough to grind various grains, including wheat, corn, and rice, and can even be adapted to grind spices with an additional accessory. This versatility can be beneficial for businesses that require different types of flour or ground materials. The build is sturdy and heavy-duty, meant to withstand significant use without overloading, and it includes safety certifications from UL, CSA, and CE, ensuring reliable performance and safety. The easy-clean cyclo-canister and filtration tube help minimize mess, simplifying the cleaning process—a valuable feature in a busy kitchen environment.

However, at 10.3 pounds, it is relatively heavy, which may pose a challenge for frequent relocation. While it's not the most affordable option on the market, the lifetime warranty adds significant value and peace of mind. With an impressive customer rating of 4.7 out of 5 stars, it suggests a high level of satisfaction among users. This grain mill is well-suited for those needing a fast, reliable, and versatile grinding solution, especially in settings where performance and nutrient preservation are crucial.

Most important from

1361 reviews

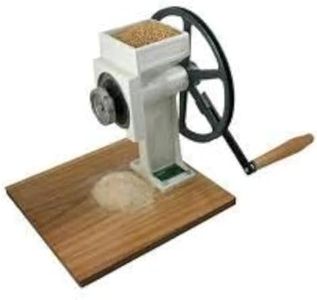

Country Living Grain Mill with Large Corn & Bean Auger

Most important from

68 reviews

The Country Living Grain Mill with Large Corn & Bean Auger is a hand-crank grain mill known for its durability and versatility. With a solid build, this mill is made from high-quality materials, making it a long-lasting investment for anyone needing to grind grains regularly. Its hand-crank mechanism ensures that it can be used anywhere without requiring electricity, which is beneficial for settings with unreliable power sources.

The adjustable setting allows users to control the fineness of the flour, catering to different needs and preferences efficiently. However, being manually operated, it might demand significant effort and time, especially when grinding large quantities. Additionally, its weight of over 20 pounds makes it less portable and potentially cumbersome to move around.

Cleaning the device might require some effort due to its intricate parts, but its sturdy construction and reliable grinding mechanism make it a strong contender for those looking for a manual, non-electric grain mill solution. This product is ideal for small to medium-sized farms, home bakers, or anyone in a rural setting who values self-sufficiency and quality milling.

Most important from

68 reviews

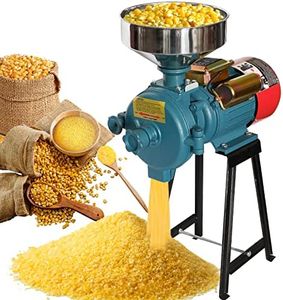

NAIZEA Grain Mills Wet Dry Cereals Grinder, Electric Grain Mill Grinder Corn Mill, Heavy Duty 3000W 110V Commercial Grain Grinder Machine, Wheat Feed Mill Flour Mill with Funnel (Dry & Wet Grinder)

Most important from

131 reviews

The NAIZEA Grain Mill stands out with its impressive capacity and robust power source. It can handle up to 166 pounds, making it suitable for commercial use where large quantities need to be processed quickly. The 3000W motor ensures efficient and powerful grinding, supported by its 110V connection.

This mill is versatile, capable of both wet and dry grinding thanks to its interchangeable sand and steel milling discs. This dual functionality is ideal for diverse applications, from making soy milk to grinding corn for flour. The construction material, primarily aluminum alloy, enhances durability and prevents rust, which is a significant benefit for long-term use in a commercial setting.

The weight and industrial style of the machine might not appeal to everyone, especially if space and aesthetics are a concern. Adjustability in grinding is a plus, but it’s important to note that ease of cleaning might be challenging due to its heavy-duty build and multiple components. This product is best suited for commercial users or households with high-volume grain grinding needs who can benefit from its powerful performance and versatility.

Most important from

131 reviews

Buying Guide for the Best Commercial Grain Mills

Choosing the right commercial grain mill is crucial for your business, whether you're running a bakery, a brewery, or any other establishment that requires freshly milled grains. The right mill can improve the quality of your products, increase efficiency, and ensure consistency. When selecting a grain mill, it's important to consider several key specifications to ensure you get the best fit for your needs.FAQ

Most Popular Categories Right Now