10 Best Glues For Inflatable Boats 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

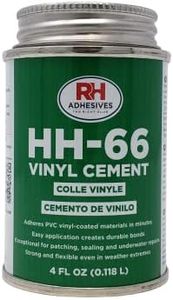

HH-66 Vinyl Cement, 4 oz. can - RH Adhesives

Most important from

9247 reviews

The HH-66 Vinyl Cement by RH Adhesives is a strong contender for gluing inflatable boats. It's specifically designed to work with vinyl and plastic materials, making it a good match for most inflatable boat surfaces. One of its standout features is its excellent water resistance, even performing reliably underwater. This ensures that repairs made with this adhesive will hold up well in marine environments. The adhesive can be applied in a wide range of temperatures, from 35 to 95 degrees Fahrenheit, adding to its versatility in different weather conditions.

Another plus is its flexibility, which means it won't crack or become brittle over time, maintaining the integrity of the inflatable boat as it flexes and moves in use. The application method is user-friendly thanks to the included brush, ensuring the adhesive goes on smoothly whether using it on the fabric or hard plastic parts of the boat. As a solvent-based adhesive, it could emit strong fumes, so good ventilation is necessary during application.

Made in the USA, this product has a reputation for quality and reliability, backed by RH Adhesives' long-standing history since 1949. The HH-66 Vinyl Cement is a solid choice for repairing and maintaining inflatable boats, with its water resistance, flexibility, and material compatibility being its primary strengths.

Most important from

9247 reviews

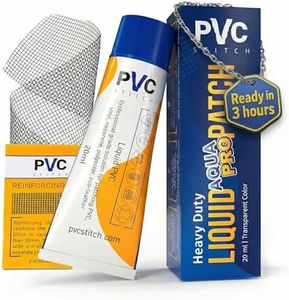

PVC Stitch Liquid Repair Patch for Air Mattresses, Waterbeds, Glue Inflatable Boats, Rafts, ISUPs, above-Ground Pools, Bouncy Houses, Hot Tubs, Air Tracks, Works on Blow up PVC & PU Inflatables

Most important from

2165 reviews

The PVC Stitch Liquid Repair Patch is a versatile and durable glue designed for a range of inflatable materials, including PVC and PU. It's notable for its strong material compatibility, making it suitable for repairing air mattresses, waterbeds, above-ground pools, inflatable boats, and more. The adhesive is water-resistant, which is crucial for outdoor and water-related repairs.

It also boasts UV and temperature resistance, ensuring durability in various environmental conditions. The curing time is relatively fast, with a usable time of 2 hours and maximum strength reached in 6 hours, suitable for quick repairs. The application method is straightforward: apply the liquid PVC evenly over the damaged area, and it cures into a permanent patch without the need for additional patches.

This simplicity makes it user-friendly, even for those with little repair experience. However, it does not work on nylon-based materials, which is a limitation if you need to repair nylon items. The product comes in a small 20 milliliter tube, which may not be sufficient for larger repairs. PVC Stitch is a reliable choice for quick and durable repairs on a variety of inflatable PVC and PU items, though its limited material compatibility and small tube size should be considered.

Most important from

2165 reviews

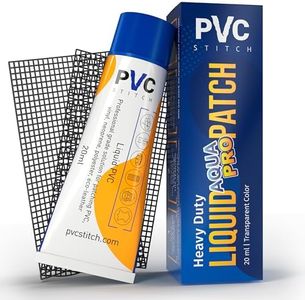

AquaPro Liquid Patch Waterproof Repair Kit for PVC Inflatable Boats, Rafts, ISUPs, Paddle Boards, above Ground Pools, Hot Tubs, and Underwater Gear | Sealer +Cord |

Most important from

1619 reviews

The AquaPro Liquid Patch Waterproof Repair Kit is designed especially for repairing PVC and PU inflatable boats, rafts, paddle boards, and similar outdoor water gear. It works well with materials like PVC and polyurethane but does not suit nylon-based fabrics, so it's important to check your item's material first. This kit is highly water-resistant, UV resistant, and can handle a wide range of temperatures, making it a reliable choice for saltwater and outdoor use. The curing time is reasonably quick, allowing you to use the repaired item after about 2 hours at room temperature, which is handy for field repairs. The kit includes a liquid sealant and a PVC mesh cord that adds strength for larger tears, although smaller repairs don’t require the cord.

Application is straightforward—just clean and dry the damaged area, apply the sealant (with or without cord), and let it cure without spreading it too thin. The glue remains flexible after curing, maintaining the inflatable’s shape and durability over time. One limitation is that the kit comes in a small 20 ml tube, so very large or multiple repairs might require more product. Also, it doesn’t work on all materials, so it’s best suited for those mainly dealing with PVC or PU inflatables. For those seeking a dependable, easy-to-use repair solution for inflatable water gear with good water and temperature resistance, AquaPro presents a practical option.

Most important from

1619 reviews

Buying Guide for the Best Glues For Inflatable Boats

Choosing the right glue for inflatable boats is crucial to ensure durability, safety, and longevity of your boat. The glue you select must be compatible with the material of your boat, provide a strong bond, and be resistant to water and environmental conditions. Here are some key specifications to consider when selecting glue for inflatable boats, along with explanations to help you make the best choice for your needs.FAQ

Most Popular Categories Right Now