10 Best 12 Inch Miter Saw Blade 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Diablo Combination Saw Blade for Wood - 12" Diameter, 60 Comb Teeth, 1" Arbor, .118" Kerf, 15° Hook Angle, .071" Plate, 6,000 Max RPM - D1260X

The Diablo 12-inch Combination Saw Blade is designed for versatile woodcutting, offering a good balance between ripping and crosscutting thanks to its 60 teeth. This tooth count is a solid middle ground, providing relatively smooth cuts without sacrificing speed, making it suitable for general woodworking projects. The blade features a super-thin .118-inch kerf, which means it removes less material during cutting, resulting in less waste and requiring less power from your saw.

Its high-performance titanium carbide teeth with a 15° hook angle help deliver fast, clean cuts and contribute to the blade's longevity. Additionally, the Perma-SHIELD coating protects against heat and corrosion, which keeps the blade performing well over time and reduces the chance of gumming. The hardened steel body and tri-metal brazing add extra durability, so this blade is less likely to chip or wear out quickly.

While the 60-tooth configuration is versatile, it may not provide the ultra-smooth finish that blades with more teeth offer, especially for fine finishing tasks. The 1-inch arbor size fits most standard miter saws, but users should confirm compatibility with their tool. This blade serves as a reliable choice for homeowners and hobbyists needing a durable, all-purpose blade that performs well in various cutting situations without the need for frequent blade changes.

Evolution Power Tools 12BLADESS Stainless Steel Cutting Saw Blade, 12-Inch x 80-Tooth, Yellow

Most important from

3940 reviews

The Evolution Power Tools 12BLADESS is a 12-inch saw blade specifically designed for cutting stainless steel and other metals. With its 80 carbide teeth, this blade promises a fine, precise cut. The high tooth count means it can provide smoother cuts, which is ideal for detailed and delicate metalwork.

The blade’s 0.083-inch kerf allows for minimal material wastage, which can be beneficial for those working with expensive metals. The carbide material enhances durability, ensuring the blade remains sharp for longer periods, reducing the need for frequent replacements. However, it is important to note that this blade is designed to operate at 1600 RPM and is best suited for Evolution saws or other low RPM saws.

This limitation means users with high-speed saws might find it inefficient or potentially damaging. Weighing in at just 1 pound, the blade is lightweight and easy to handle. It's a solid choice for professionals and hobbyists looking to cut stainless steel with precision, as long as they have the appropriate saw to match the blade's specifications.

Most important from

3940 reviews

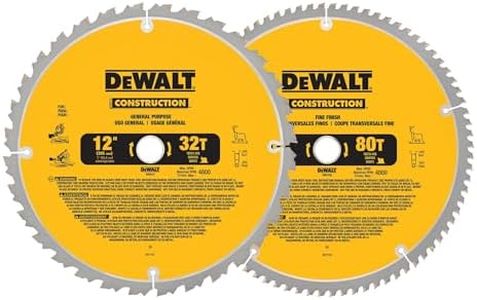

DEWALT 12-Inch Miter Saw Blade, Crosscutting, Tungsten Carbide, 80-Tooth and 32-Tooth, 2-Pack (DW3128P5, DW3123), yellow

Most important from

5229 reviews

The DEWALT 12-Inch Miter Saw Blade set includes both an 80-tooth blade for fine crosscutting and a 32-tooth blade for more aggressive cuts. This versatility makes it ideal for users who may need different types of cuts depending on the project. The tungsten carbide material ensures durability and longevity, providing sharpness that holds up well through multiple uses. Users can expect smooth, accurate cuts, which is essential for woodworking and construction tasks.

One strength of this product is its ability to handle engineered wood effectively, making it a great choice for those working with various materials. The blades are designed to work seamlessly with DEWALT miter saws, but they are also compatible with many other brands, enhancing their utility. The lightweight design makes handling and installation straightforward, even for less experienced users.

There are a few considerations to keep in mind. While the 80-tooth blade excels in fine cuts, it may not be as effective for ripping or larger cuts due to the finer tooth count. The 32-tooth blade, while suitable for faster cuts, may not provide the same level of finish as the higher tooth count blade. Therefore, users doing a lot of detailed work may need to switch blades frequently. Additionally, while the price point is generally reasonable, budget-conscious users might find similar products available at lower prices without the DEWALT branding.

Most important from

5229 reviews

Buying Guide for the Best 12 Inch Miter Saw Blade

Choosing the right 12-inch miter saw blade is crucial for achieving clean, precise cuts in your woodworking projects. The right blade can make a significant difference in the quality of your work, the efficiency of your cuts, and the longevity of your saw. To make an informed decision, you need to understand the key specifications of miter saw blades and how they relate to your specific needs.FAQ

Most Popular Categories Right Now