10 Best 60 Gallon Air Compressors 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Klutch 60-Gallon Single-Stage Vertical Air Compressor, 3.7 HP, 230 Volts

Most important from

450 reviews

The Klutch 60-Gallon Single-Stage Vertical Air Compressor is a solid choice for those needing a mid-sized, powerful air compressor for home workshops or light commercial use. It features a strong 3.7 HP motor that delivers 9.3 CFM at 90 PSI, suitable for running a variety of pneumatic tools efficiently. The maximum pressure of 135 PSI offers enough power for most tasks in its class. The 60-gallon vertical tank allows for longer tool run times without frequent motor cycling, which is good for consistent work.

The oil-lubricated pump with cast iron construction and stainless steel valves adds durability and reliability, meaning the compressor can handle repeated use over time. The unit weighs 220 pounds and is not designed for portability, so it’s best suited to a fixed workspace rather than moving around frequently. The compressor runs on 230 volts, so it requires the appropriate power source, which might limit use in some home settings without electrical upgrades. This model has received favorable user ratings, indicating satisfaction with its performance and build quality.

This compressor is a dependable and powerful option if you need a steady air supply for medium-duty jobs and don’t require portability. Additionally, oil-lubricated compressors tend to be quieter than oil-free models, which is a plus for indoor use.

Most important from

450 reviews

California Air Tools 60040DCAD 4.0 HP Ultra Quiet and Oil-Free Air Compressor, 60 Gallon Steel Tank, 75 dBA Noise Level, with Air Drying System and Auto Drain

Most important from

74 reviews

The California Air Tools 60040DCAD is a 60-gallon air compressor designed for users who need a quiet yet powerful machine, such as hobbyists or professionals working in noise-sensitive environments. It runs at a relatively low noise level of 75 decibels, which is significantly quieter than many compressors, making it suitable for indoor use or workshops where noise is a concern. The compressor features twin 2.0 HP motors that provide a total of 4.0 horsepower, supporting a strong airflow of 12.8 CFM at 40 PSI and 10.6 CFM at 90 PSI. This means it can handle tasks like airbrushing, cleaning, or tire inflation without struggling.

Its 60-gallon steel tank offers plenty of air storage, allowing longer work periods between cycles. The oil-free dual piston pump means less maintenance and cleaner air, which is a plus if you want to avoid frequent oil changes or contamination. Additionally, the built-in 80% air dryer and aftercooler help reduce moisture in the air, improving tool performance and lifespan. The automatic drain valve makes upkeep easier by removing the need for manual water draining.

On the downside, this model is relatively heavy at 248 pounds, which limits portability, so it's best suited for stationary use in a workshop or garage. Also, while 75 decibels is quiet for this type of equipment, it’s not silent and might still be noticeable in very quiet settings. Finally, the unit requires 220 volts, so it may not work with standard household outlets without proper wiring. This compressor effectively balances power, quiet operation, and low maintenance, making it a solid choice for those needing reliable air delivery without excessive noise.

Most important from

74 reviews

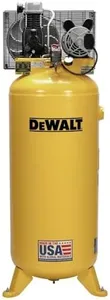

DEWALT 60 Gallon Vertical Air Compressor, Stationary, 3.7 HP, 175 Max PSI, Oil Lubricated, ASME Tank, Industrial-Grade Performance for Reliable Use in Workshop or Garage

Most important from

9 reviews

The DEWALT DXCM602.COM 3.7 HP 60 Gallon Air Compressor is a solid option for those in need of a powerful and reliable stationary air compressor. With a robust 3.7 HP motor, it reaches an impressive maximum pressure of 175 PSI, making it suitable for a variety of demanding tasks such as spraying, nailing, and grinding. The compressor provides a commendable air flow of 11.5 CFM at 90 PSI, ensuring that it can efficiently power multiple pneumatic tools simultaneously.

One of the strengths of this model is its oil-lubricated system, which promotes smooth operation and extends its lifespan by reducing wear and tear. Additionally, the compressor meets high safety standards with an ASME-certified tank, providing peace of mind for users concerned about safety during operation.

There are a few considerations to keep in mind. The noise level at 87 dB is relatively high, which may not sit well with those sensitive to loud sounds or in noise-sensitive environments. Additionally, while it offers versatility with its 208V and 230V compatibility, its stationary nature and weight of 200 pounds can make it less portable than some users might prefer. This compressor is best suited for professionals or serious DIY enthusiasts who require steady and reliable air pressure for heavy-duty tasks.

Most important from

9 reviews

Buying Guide for the Best 60 Gallon Air Compressors

Choosing the right 60-gallon air compressor can significantly impact the efficiency and effectiveness of your work, whether you're using it for professional tasks or DIY projects. The key is to understand the various specifications and how they align with your specific needs. By focusing on the right specs, you can ensure that you get a compressor that meets your requirements without overpaying for features you don't need.FAQ

Most Popular Categories Right Now