10 Best Cylinder Bore Gauges 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Mitutoyo 511-931 Dial Bore Gauge, 0.7"-6" Range, 0.0005" Graduation, +/-0.0008" Accuracy

The Mitutoyo 511-931 Dial Bore Gauge is a solid choice for those needing precision measurement in the realm of cylinder bores. With a measurement range of 0.7 to 6 inches, it caters well to various applications, making it suitable for both hobbyists and professionals in the engineering or automotive fields. The gauge boasts impressive accuracy of +/-0.0008 inches, which is essential for quality control in any machining process. Its graduation of 0.0005 inches allows for meticulous readings, ensuring you can detect even the slightest deviations in bore sizes.

One of the standout features is its two-point contact system, which helps in identifying geometry problems such as ovality and taper. This is particularly useful for users who need to ensure that their cylinder bores are perfectly round and uniform. The carbide-tipped contact points enhance durability, providing extended wear and resistance to damage, which is a significant advantage over standard materials.

While the rugged cover offers protection for the dial indicator, some users might find the gauge a bit bulky or heavy at 5.1 pounds, making it less portable for on-site measurements. Additionally, while it is designed for ease of use, beginners may still require some time to familiarize themselves with the proper technique for accurate readings. The Mitutoyo 511-931 is an excellent tool for those needing a reliable bore gauge, especially in industrial or mechanical settings. Its accuracy and build quality stand out, but potential users should consider its weight and the learning curve associated with its use.

Mitutoyo-511-753 Dial Bore Gage, 2-6 in, 0.0001 in Res

Most important from

88 reviews

The Mitutoyo-511-753 Dial Bore Gage is a reliable choice for those needing precise measurements in the 2-6 inch range. With a resolution of 0.0001 inches, it offers exceptional detail, making it suitable for both professional and hobbyist applications. The build quality is commendable, as it is made in Japan, a country known for its manufacturing precision, ensuring durability and trustworthy performance.

One of the standout features is its ease of use, which is important for users who may not be experienced with bore gauges. The dial indicator is clear and easy to read, allowing for quick interpretation of results. Additionally, its lightweight design (2 pounds) contributes to comfortable handling during measurements, which is a plus for extended use.

There are some factors to consider. While it has a solid measurement range and excellent resolution, the accuracy of the tool can be influenced by how well it's maintained. Users should ensure it’s calibrated correctly to maintain precision. There may also be a learning curve for complete beginners to fully understand how to leverage all its features effectively. In terms of additional features, this model is straightforward without many bells and whistles, which could be a drawback for those looking for more advanced functionalities. Nonetheless, it performs well within its primary purpose, making it a strong candidate for machinists, engineers, and anyone involved in mechanical work needing precise bore measurements.

Most important from

88 reviews

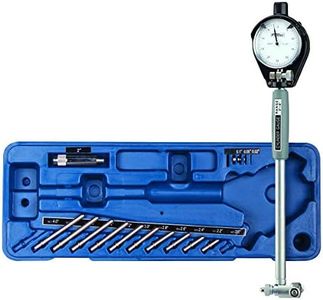

Neoteck 1.4-6"/0.0005" Digital Indicator Bore Gauge Set with 15PCS Anvils 6" Measuring Depth Dial Bore Gauge with ABS Storage Box for Engine Cylinder Measurement

Most important from

403 reviews

The Neoteck Digital Indicator Bore Gauge Set is designed to measure internal diameters in engine cylinders and similar parts, covering a range from 1.4 to 6 inches with a high precision of 0.0005 inches and an accuracy error margin of 0.001 inches. This makes it a solid choice for mechanics or hobbyists who need reliable measurements for engine blocks or pistons. The gauge uses a two-point contact system and comes with 15 interchangeable anvils, which allows you to measure a wide variety of hole sizes without needing additional tools.

Its digital indicator has a clear LCD screen with easy functions like zero setting, unit switching, and data holding, which helps reduce mistakes and speeds up the measuring process. The build quality is decent, featuring a sturdy chrome-plated aluminum handle with an ergonomic design for comfortable use over longer periods. The kit is neatly organized in a durable ABS storage case, making it convenient to keep all parts together and transport them safely.

The measuring depth is limited to 6 inches, which might not suit some deeper measurements. Also, it uses a small LR44 battery, which is included but may need regular replacement depending on usage. This product suits users needing precise cylinder bore measurements within its specified range, combining accuracy, ease of use, and good value in one package.

Most important from

403 reviews

Buying Guide for the Best Cylinder Bore Gauges

Choosing the right cylinder bore gauge is essential for ensuring accurate measurements of the internal diameter of cylinders, which is crucial in various mechanical and engineering applications. To make an informed decision, you need to understand the key specifications and how they align with your specific needs. Here are the main factors to consider when selecting a cylinder bore gauge.FAQ

Most Popular Categories Right Now