10 Best Diamond Blade For Granite 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

14" All Purpose Diamond Saw Blades for Hard/Reinforced Concrete, Asphalt, Granite, Terrazzo, Ductile Iron Piping, 4-5/8" Cutting Depth, 1" Arbor

This 14-inch diamond saw blade is a versatile choice for cutting hard materials such as granite, reinforced concrete, asphalt, terrazzo, and ductile iron piping. With a robust 10mm segment height and 0.125-inch segment width, it offers good durability and efficiency for medium-depth cuts—up to about 4-5/8 inches deep. The 1-inch arbor size is a common fit for many handheld and walk-behind saws, making it fairly easy to use with standard equipment. It’s designed for both wet and dry cutting, though using water can help extend blade life and reduce dust.

While the blade is multipurpose, it may not be optimized for ultra-precise granite work where finer segment design or softer/harder bond variations could improve finish and cutting speed. Also, with a thickness of 3 millimeters and 24 teeth, it balances cutting speed and blade stability but may cut a bit slower compared to more specialized blades.

If you need a reliable all-around blade for various tough materials, this model offers solid performance, though for heavy granite cutting tasks, a blade specifically designed for granite might deliver smoother results.

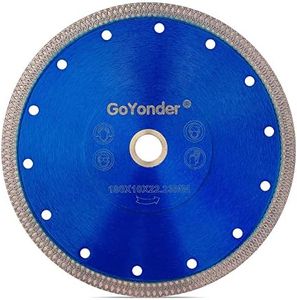

4.5" Diamond Blade for Angle Grinder, Super Thin Tile Saw Blades for Smooth Cutting, 2Pcs Indestructible Disc for Grinder Cutting Porcelain Ceramic Tile Granite Marbles.

Most important from

775 reviews

This 4.5-inch diamond blade from ZORUNNA is a solid choice if you need a blade for smooth, precise cuts on granite, porcelain, ceramic, and marble tiles. Its ultra-thin design and 45 teeth with a turbo mesh rim help reduce chipping and make cutting faster and cleaner, which is great for detailed work. The blade works well both wet and dry, so you have flexibility depending on your cutting setup. It’s built with a thicker core that minimizes vibration, improving safety and making your cutting more stable. The 7/8-inch arbor size fits most standard angle grinders and tile saws, which is convenient.

One downside is the blade's very thin segment height (about 1/20 inch), which might wear out faster if used heavily on hard materials like granite. While the manufacturer highlights durability, very frequent or heavy use on tough granite may require replacement sooner than with some industrial blades. If you plan to cut a variety of tiles or lighter masonry alongside granite, this blade provides decent versatility without needing multiple blade swaps.

Remember to follow safety tips and use protective gear, especially since it handles dry cutting too. This blade is well suited for DIYers and light professional use who want an affordable, precise tool for tile and granite projects.

Most important from

775 reviews

EZARC 4-1/2 inch Super Thin Diamond Blade, Diamond Saw Blades for Angle Grinder, 4.5" Tile Blade for Smooth Cutting Porcelain Ceramic Granite Marble Tile, 7/8"-20mm-5/8 Arbor (2-Pack)

Most important from

1487 reviews

The EZARC 4-1/2 inch Super Thin Diamond Blade is designed primarily for cutting tiles such as porcelain, ceramic, granite, and marble. Its 4.5-inch diameter and thin 1.2mm segment thickness make it excellent for precise, clean cuts with less risk of chipping, which is great if you value neat results especially on delicate or detailed tile work. The 10mm segment height provides a decent balance between cutting depth and durability for light to moderate tasks. Compatible with most angle grinders and tile saws that use a 7/8" arbor (with an included adapter for 5/8"), it offers flexibility for common tools.

The blade supports both wet and dry cutting, but using it wet helps extend its life significantly, which is important when cutting tougher materials like granite. It also operates at high speeds (up to 13,300 RPM) safely thanks to its alloy steel body and premium diamond coating, reducing sparks and burn marks. On the downside, its super thin design, while good for precision, means it may wear out faster under heavy or frequent use compared to thicker blades. It is better suited for tile and light granite cutting rather than deep or very heavy-duty granite work.

If you are a DIYer or a tile installer needing sharp, clean cuts on a variety of hard surfaces without heavy industrial use, this blade is a solid choice. For more intense granite cutting, a thicker, more robust blade might be necessary.

Most important from

1487 reviews

Buying Guide for the Best Diamond Blade For Granite

Choosing the right diamond blade for cutting granite is crucial to ensure efficiency, precision, and safety. Granite is a hard and dense material, so the blade you select must be capable of handling such a tough job. Understanding the key specifications of diamond blades will help you make an informed decision and achieve the best results for your specific needs.FAQ

Most Popular Categories Right Now