We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

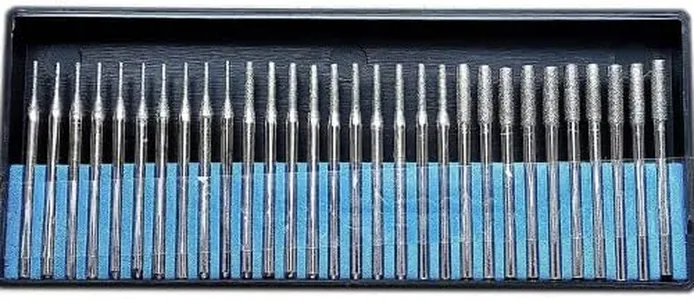

10 Best Diamond Drill Bits 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Diamond Drill Bits

Choosing the right diamond drill bit can make a significant difference in the efficiency and quality of your drilling projects. Diamond drill bits are designed for drilling through hard materials like glass, stone, and ceramics. To select the best diamond drill bit for your needs, you should consider several key specifications. Understanding these specifications will help you make an informed decision and ensure that you get the best performance for your specific application.DiameterThe diameter of a diamond drill bit refers to the width of the hole it will create. This is important because it determines the size of the hole you can drill. Diameters can range from very small (a few millimeters) to quite large (several centimeters). If you need to drill small, precise holes, choose a bit with a smaller diameter. For larger holes, select a bit with a larger diameter. Consider the size of the material you are working with and the requirements of your project when choosing the diameter.

Shank TypeThe shank type of a diamond drill bit is the part that fits into the drill. Common shank types include round, hex, and SDS. The shank type is important because it affects the compatibility with your drill. Round shanks are versatile and fit most standard drills, hex shanks provide a better grip and are less likely to slip, and SDS shanks are designed for use with hammer drills. Choose a shank type that matches your drill and the type of work you will be doing.

Bond TypeThe bond type of a diamond drill bit refers to how the diamonds are attached to the bit. There are mainly two types: electroplated and sintered. Electroplated bits have a single layer of diamonds bonded to the surface, making them ideal for precision work and softer materials. Sintered bits have multiple layers of diamonds, making them more durable and suitable for harder materials and longer use. Choose electroplated bits for delicate, detailed work and sintered bits for heavy-duty, prolonged drilling.

Grit SizeGrit size indicates the size of the diamond particles on the drill bit. It affects the smoothness and speed of the drilling process. Finer grits (higher numbers) produce smoother finishes and are better for delicate materials, while coarser grits (lower numbers) remove material faster and are suitable for harder, more abrasive materials. If you need a smooth finish and are working with delicate materials, choose a finer grit. For faster drilling in harder materials, opt for a coarser grit.

Cooling MethodDiamond drill bits generate a lot of heat, so cooling methods are crucial to prevent damage to the bit and the material. Common cooling methods include water and air. Water-cooled bits are ideal for continuous use and help extend the life of the bit by reducing heat. Air-cooled bits are more convenient for quick, intermittent drilling. If you plan to drill for extended periods, choose a water-cooled bit. For shorter, less frequent drilling, an air-cooled bit may be sufficient.

Most Popular Categories Right Now