We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

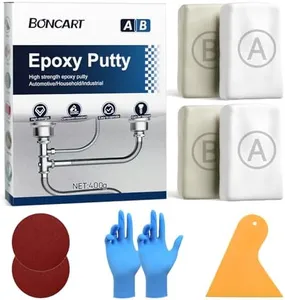

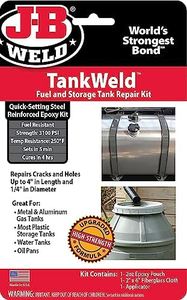

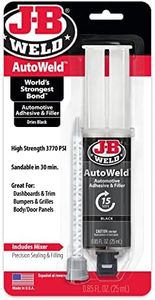

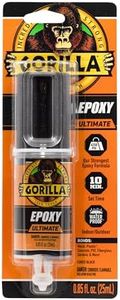

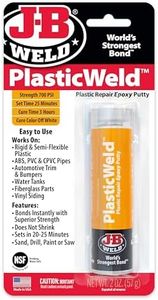

10 Best Epoxy For Plastic Radiator Repair 2026 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Epoxy For Plastic Radiator Repair

When it comes to repairing a plastic radiator, choosing the right epoxy is crucial for ensuring a durable and long-lasting fix. Epoxy is a type of adhesive that can bond materials together, and it is particularly useful for repairing cracks or leaks in plastic radiators. To select the best epoxy for your needs, you should consider several key specifications that will determine the effectiveness and suitability of the product for your specific repair job. Understanding these specifications will help you make an informed decision and achieve the best results.Curing TimeCuring time refers to the amount of time it takes for the epoxy to fully harden and reach its maximum strength. This is important because it affects how quickly you can use the repaired radiator. Epoxies with shorter curing times (e.g., 5-10 minutes) are ideal for quick fixes and emergency repairs, while those with longer curing times (e.g., several hours) may provide a stronger bond and are better for more permanent repairs. Consider how urgently you need the repair to be completed and whether you can afford to wait for a longer curing time.

Temperature ResistanceTemperature resistance indicates the maximum temperature that the epoxy can withstand without losing its adhesive properties. This is crucial for radiator repairs because radiators operate at high temperatures. Epoxies with higher temperature resistance (e.g., up to 250°F or higher) are better suited for radiator repairs as they can handle the heat without breaking down. If your radiator operates at particularly high temperatures, make sure to choose an epoxy with a high temperature resistance to ensure a durable repair.

Chemical ResistanceChemical resistance refers to the epoxy's ability to withstand exposure to various chemicals, such as coolant and antifreeze, which are commonly found in radiators. This is important because the epoxy needs to maintain its bond and integrity even when in contact with these substances. Look for epoxies that specifically mention resistance to automotive fluids and chemicals. If your radiator is exposed to harsh chemicals, choosing an epoxy with high chemical resistance will ensure a longer-lasting repair.

FlexibilityFlexibility is the ability of the epoxy to bend or flex without cracking. This is important for plastic radiator repairs because plastic can expand and contract with temperature changes. An epoxy with good flexibility will accommodate these movements without breaking the bond. If your radiator is subject to frequent temperature fluctuations, opt for an epoxy that offers flexibility to ensure the repair remains intact over time.

Ease of ApplicationEase of application refers to how simple and straightforward it is to use the epoxy. This includes factors like whether it comes in a pre-mixed form, how easily it can be applied to the repair area, and whether it requires any special tools or preparation. For DIY repairs, an epoxy that is easy to apply can save time and reduce the risk of errors. If you are not experienced with using epoxy, look for products that are user-friendly and come with clear instructions.

Most Popular Categories Right Now