10 Best Flush Cutters 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

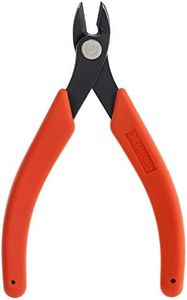

BOENFU Small Wire Flush Cutters 5-in, Sharp and Precision Side Cutting Pliers with Spring, Small Wire Snips for Jewelry Making, Model Cutting, Electronic - Black

Most important from

10543 reviews

The BOENFU Small Wire Flush Cutters are designed for precision and versatility. Made with high-quality chrome vanadium steel and alloy steel, the blades are durable and capable of cutting wire up to 14 gauge, which makes them suitable for a variety of tasks including jewelry making, model cutting, and electronic work. The precision-crafted blades offer exceptional control and accuracy, which is particularly beneficial for detailed and intricate projects.

One of the standout features is the ergonomic grip, designed to minimize hand cramps and provide steady control, making extended use more comfortable. The integrated spring mechanism helps reduce hand fatigue by automatically reopening the jaws after each cut, which is a convenient feature for repetitive tasks. Weighing only 2.89 ounces and measuring 5 inches, these cutters are lightweight and easy to handle.

The BOENFU Small Wire Flush Cutters are best suited for hobbyists, DIY enthusiasts, and professionals who require precise and reliable cutting tools for delicate work.

Most important from

10543 reviews

Klein Tools D275-5 Pliers, Diagonal Cutting Pliers with Precision Flush Cutter is Light and Ultra-Slim for Work in Confined Areas, 5-Inch

Most important from

7619 reviews

The Klein Tools D275-5 Diagonal Flush Cutters are designed for precise, clean cuts on small wires, zip ties, and other fine materials, making them ideal for tasks that require accuracy and neatness. The blades are made from heat-treated alloy steel, offering good durability. With a cutting capacity up to 16 AWG wire and a cutting width of 0.26 inches, they handle most small wiring jobs effectively. The flush cutting feature means cuts are flat and smooth, which is especially helpful when working with zip ties to avoid sharp edges.

The slim, compact design allows easy access in tight spaces, which is great if you're often working in confined areas. The ergonomic handles and built-in steel return spring enhance comfort, reducing hand fatigue during repetitive use. The tool is on the smaller side (5 inches), which might limit leverage and strength for cutting thicker or tougher materials. Also, while the tool is sturdy, the alloy steel construction may not be as tough as some high-end steel variants.

This cutter suits electricians, hobbyists, and anyone needing precise trimming of small wires and zip ties, but it may not be the best choice for heavy-duty cutting.

Most important from

7619 reviews

KATA Wire Cutters Plier for Crafting - Heavy Duty 6 Inch Flush Side Cutter Metal Cutting Tool with Safety Cap - Sharp Snips For Zip Tie, Jewelry, Floral, Artificial Flowers, Chicken Wire, Electrical

Most important from

3816 reviews

The KATA Wire Cutters Plier is a sturdy and reliable tool made with chrome vanadium steel, which keeps the blades sharp and durable for repeated use. Its flush-cutting jaws and angled head design help provide clean, precise cuts, making it especially useful for cutting wires up to about 12 AWG (around 2.6 mm thick). This cutting capacity covers many common tasks like trimming zip ties, jewelry wire, chicken wire, and even floral or artificial flower stems.

The handles have a comfortable PVC grip, which feels good in the hand, and the spring-loaded mechanism makes it easier to use repeatedly without tiring your fingers. This is helpful whether you're a hobbyist, electrician, or someone doing home repairs. One thoughtful safety feature is the plastic cap that covers the sharp jaws when not in use, reducing the chance of accidental cuts during storage.

The tool isn't designed for very thick or hardened steel wires, and attempting to cut these could damage the blades. While the ergonomic handles aid comfort, users with larger hands might find the 6-inch size a bit small for heavy-duty work. The KATA flush cutters perform well for a wide range of light to medium wire-cutting jobs, offering sharp performance and comfort, especially within their specified thickness limits and not for the toughest metals.

Most important from

3816 reviews

Buying Guide for the Best Flush Cutters

Flush-cutters are essential tools for anyone working with electronics, jewelry making, or any task that requires precise cutting of wires or small components. Choosing the right flush-cutter can make your work easier, more efficient, and ensure clean cuts without damaging the surrounding material. When selecting a flush-cutter, consider the following key specifications to find the best fit for your needs.FAQ

Most Popular Categories Right Now