10 Best Heavy Duty Bar Clamps 2026 in the United States

Winner

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

JORGENSEN 36-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

Most important from

1109 reviews

The JORGENSEN 36-inch Bar Clamps, 90° Cabinet Master Parallel Jaw Bar Clamp Set, come in a two-pack and offer a maximum opening capacity of 36 inches, making them suitable for large woodworking projects. These clamps are designed to exert up to 1500 lbs of clamping force, thanks to their heavy-duty steel jaws and high-carbon steel bar, which ensures durability and strength during use. This makes them ideal for tasks such as panel glue-ups, boxes, cabinets, frames, and raised panel doors.

The clamps feature reinforced steel and castings protected by orange plastic that add strength to the jaws, enhancing their reliability and longevity. The reversible head allows for spreader clamping, adding versatility, while the clamp stand provides easy adjustments. Additionally, the maple handles are ergonomically designed to be comfortable and prevent hand wear during long periods of use.

However, these clamps are relatively heavy, at nearly 17 pounds per pair, which might make them slightly cumbersome for some users to handle. Their size and weight could be a drawback if frequent transportation or varied work environments are necessary. This product is particularly well-suited for serious woodworkers or those engaged in heavy-duty projects that require substantial clamping force and reliable adjustability.

Most important from

1109 reviews

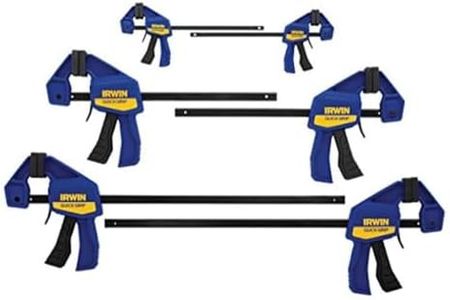

IRWIN QUICK-GRIP Bar Clamp, One-Handed Clamp/Spreader, 24-Inch (1964720), Blue

Most important from

2752 reviews

The IRWIN QUICK-GRIP 24-inch bar clamp is a strong and user-friendly tool designed for heavy-duty clamping needs. It offers a solid clamping capacity of 24 inches and can maintain up to 300 pounds of clamping force, which is quite reliable for woodworking, metalworking, or DIY projects. The I-beam bar is made from heat-treated black oxide carbon steel, making it resistant to bending and flexing under pressure, a key feature for durability and stability during tough jobs.

The clamp’s handle and trigger design allow for one-handed operation, which is convenient when you are juggling multiple tools or materials. Its quick-release trigger makes it easy to adjust or remove the clamp quickly, saving time during work. The swivel jaws come with removable, non-marring pads that protect your workpieces from scratches while distributing clamping force evenly, preventing damage and ensuring a firm hold. A standout feature is the Quick-Change button that lets you convert the clamp into a spreader, adding versatility for different tasks.

Although it’s made primarily with resin components, the main structural bar’s steel construction ensures strength where it counts. Weighing about 1.85 pounds, it is light enough to handle comfortably but still feels sturdy. One minor consideration is that while 300 pounds of clamping force is adequate for most typical heavy-duty projects, some industrial tasks might require even stronger clamps. Also, the clamp’s 24-inch capacity means it’s best suited for medium to large projects, but not for very wide materials. This clamp represents an excellent choice for hobbyists and professionals who want a reliable, versatile, and easy-to-use heavy-duty bar clamp with good adjustability and protection for their materials.

Most important from

2752 reviews

HORUSDY 12-Inch 300LBS Bar Clamps for Woodworking Heavy Duty, Quick Clamps F Clamp with 300 LBS Load Limit, 2-Pack Wood Working Clamps Sets

Most important from

1506 reviews

The HORUSDY 3-Pack 12-Inch Bar Clamps Set offers several notable features, making it a solid choice for woodworking enthusiasts and professionals alike. With a strong clamping force of up to 350 lbs, these clamps provide a secure and stable grip, ideal for both delicate and heavy-duty projects. The larger jaw pads ensure a balanced hold while protecting your materials from damage.

The universal compatibility feature is particularly useful, allowing you to integrate these clamps seamlessly with other major brands. This can be a significant advantage if you already own other clamps and seek to expand your toolkit without hassle. The high-quality steel rails and reinforced nylon handle contribute to the durability and longevity of these clamps, confirming their suitability for regular use in demanding environments.

One-handed operation is facilitated by the soft quick-release trigger, which makes these clamps easy to use and efficient, even for extended periods. Additionally, the versatile spreader functionality enhances the clamps’ adaptability, making them ideal for various project needs. However, it is important to note that these clamps may be slightly heavier than some alternatives, which could be a consideration for users who prioritize lightweight tools. This set of bar clamps from HORUSDY delivers robust performance and versatility, catering well to both hobbyists and professionals who require reliable, easy-to-use, and durable clamps for their woodworking projects.

Most important from

1506 reviews

Buying Guide for the Best Heavy Duty Bar Clamps

When it comes to picking the right heavy-duty bar clamps, it's important to consider the specific needs of your projects. Heavy-duty bar clamps are essential tools for woodworking, metalworking, and other tasks that require strong, reliable clamping pressure. The right clamp can make a significant difference in the quality and ease of your work. Here are some key specifications to consider when choosing heavy-duty bar clamps, along with explanations to help you make an informed decision.FAQ

Most Popular Categories Right Now