10 Best Metal Cutting Blade For Grinder 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

FOXBC 4-1/2 Inch Diamond Cutting Wheel Metal Cut Off for Angle Grinder, 5000+ Cuts on Rebar, Stainless Steel, Angle Iron, 7/8" Arbor - 3 Pack

Most important from

163 reviews

The FOXBC 4-1/2 inch diamond cutting wheel is designed for metal cutting tasks and fits angle grinders with a 7/8" arbor size. Its diamond abrasive rim provides a much longer cutting life—up to 100 times more durable than standard bonded discs—making it a great choice if you need a blade that lasts through many cuts, including tough materials like rebar, stainless steel, aluminum, and various pipes. The advanced electro-plating process ensures the diamond edge is evenly spread, which helps with better control and precise cuts.

The metal body of the wheel adds safety by reducing the chance of breakage, and since the diamond rimmed blade produces less dust and sparks, it offers a safer and cleaner cutting experience. This blade is primarily suitable for dry cutting and might not be the best option if you need wet cutting or very fine finish work. Also, as a diamond blade, it may come at a higher price than traditional cutoff wheels, but the durability could save you money over time.

This 3-pack gives good value for professionals or DIY users who frequently work with metal materials and want a reliable, long-lasting cutting wheel.

Most important from

163 reviews

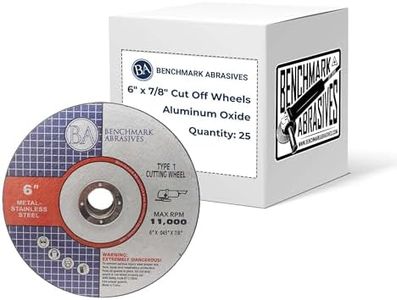

BHA Metal and Stainless Steel Thin Cut Off Wheels for Angle Grinders, 6” x .045” x 7/8” - 25 Pack

The BHA Metal and Stainless Steel Thin Cut Off Wheels are designed for angle grinders, featuring a 6-inch diameter and a very thin 0.045-inch cutting thickness. This ultra-thin design is excellent for precise cuts with minimal material waste, making it ideal for clean, efficient slicing through various metals.

Made from aluminum oxide grit, these discs deliver aggressive cutting action suitable for metal and stainless steel, fitting well with general metalworking tasks. The 7/8-inch arbor size ensures compatibility with most standard grinders. The large pack of 25 offers good value for frequent users or professional settings.

These wheels have a medium grit, which allows aggressive cutting but may not provide the smoothest finish on very delicate projects. Additionally, the absence of a specific coating could lead to more dust and debris buildup compared to coated blades that resist clogging. These wheels are a reliable choice for those needing thin metal-cutting discs to maximize material savings and efficiency.

BHA Metal and Stainless Steel Depressed Center Cut Off Wheels for Angle Grinders, 4.5” x .045” x 7/8” - 25 Pack

Most important from

858 reviews

The BHA Metal and Stainless Steel Depressed Center Cut Off Wheels come in a convenient 25-pack, making them a strong choice if you need multiple blades for frequent metal cutting tasks. Each blade has a 4.5-inch diameter and a thin 0.045-inch thickness, which helps reduce material loss and allows for precise, clean cuts. The 7/8-inch arbor size fits most standard angle grinders, so compatibility should not be an issue. These blades are made from aluminum oxide grit, known for its aggressive cutting on various metals, including stainless steel.

The depressed center design provides stability during cutting, which helps improve control and safety. These wheels use a medium grit, making them well-suited for general metal cutting rather than ultra-fine finishing work. While they perform solidly for everyday metal cutting jobs, blades with special coatings might offer longer wear when cutting harder or abrasive metals.

These wheels are ideal for DIYers or professionals who need reliable, affordable blades and a bulk supply that supports efficient work. They may not be the best option if you require specialized finishes or extended blade life.

Most important from

858 reviews

Buying Guide for the Best Metal Cutting Blade For Grinder

Choosing the right metal-cutting blade for your grinder is crucial for achieving clean, precise cuts and ensuring your safety. The right blade can make your work easier, faster, and more efficient. When selecting a blade, consider the type of metal you will be cutting, the thickness of the material, and the specific requirements of your project. Understanding the key specifications of metal-cutting blades will help you make an informed decision and select the best blade for your needs.FAQ

Most Popular Categories Right Now