10 Best Oscillating Blade For Hard Metal 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

PECHAM 23PCS Titanium & Carbide Multitool Blades Oscillating Tool Saw Blades Heavy Duty for Hard Material, Metal/Steel Nails/Bolts/Screws Fit Most Oscillating tools

The PECHAM 23PCS Titanium & Carbide Multitool Blades set is a robust option for those looking to tackle hard materials like metal, steel nails, bolts, and screws. These blades are made from high carbon steel and are enhanced with titanium and carbide coatings, which significantly boost durability. The titanium-coated blades are noted to be 50% more durable than traditional bi-metal blades, offering twice the lifespan. Meanwhile, the carbide blades are touted to last up to 30 times longer, making them highly efficient and wear-resistant for precise cuts.

One of the standout features is the universal compatibility, fitting more than 95% of oscillating tools in the market from brands like Milwaukee, Makita, and Dewalt. However, the blades are not recommended for starlock and starlock plus interface systems, and specific Dremel models (MM30, MM40, MM50). The pack includes 23 pieces with different blade types to meet various cutting needs, from wood and metal to plastics and more. This versatility makes it a good fit for both DIY enthusiasts and professionals working on home decor, workshop tasks, or general repair projects.

The weight of the entire set is reasonably manageable at 0.47 kilograms, and the dimensions are compact enough for convenient storage. A minor drawback could be their compatibility limitations with certain tool systems, which may require users to verify their tool’s compatibility beforehand. Additionally, the high specialization in blade types means users need to identify which blade suits their specific tasks. Despite these minor drawbacks, the durability and extensive applicability of the PECHAM blades make them a solid investment for demanding cutting tasks.

Diagtree Titanium Oscillating Saw Blades, Diagtree 20PCS Titanium Oscillating Multitool Blades for Metal, Wood and Plastic, fit Dewalt Milwaukee Ryobi Fein Dremel Bosch Rockwell Makita Porter Cable

The Diagtree Titanium Oscillating Saw Blades offer a robust solution for cutting through tougher materials. Their M42 high-speed steel teeth, coated with titanium, provide exceptional hardness (over HRC70) and durability, doubling the service life compared to standard Bi-metal saw blades. This makes them particularly efficient for long-term use, reducing the need for frequent replacements. The D6A steel used in the side plates also adds to their strength and reliability.

With 15 teeth per inch, these blades strike a balance between smooth cutting and efficient material removal, making them versatile for various tasks. The titanium coating helps in heat dissipation, enhancing performance and efficiency during prolonged use. These blades are compatible with a wide range of oscillating tools from major brands, thanks to the included extra adapters. However, they are not suitable for tools with starlock and starlock plus interface systems, which could be a limitation for some users.

While they are excellent for cutting mild metal, nails, copper pipes, and various other materials, they are not recommended for heat-treated steel, stainless steel, or other high-hardness materials. For home remodeling, flooring work, and general cutting needs, these blades are highly effective. Professional users dealing with extremely hard metals might need to look for more specialized blades. The Diagtree Titanium Oscillating Saw Blades are a strong choice for most home improvement and light construction tasks due to their durability, efficiency, and broad compatibility.

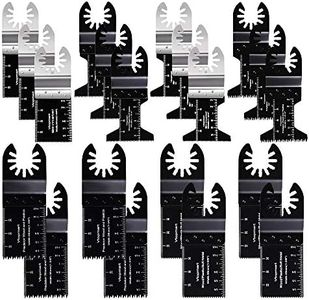

KELIN 16pcs Titanium Oscillating Tool Blades, Universal Multitool Blades for Metal Wood Cutting, Oscillating Saw Blade for Metal Hard Material, Multi Tool Blades Kits Fit Dewalt Bosch Milwaukee Ryobi

The KELIN 16pcs Titanium Oscillating Tool Blades seem well-suited for anyone needing versatile and durable blades for cutting hard metals and wood. The titanium enhancement increases the hardness by 50% and doubles the lifespan compared to ordinary bi-metal blades, which is a significant advantage for durability and performance in demanding tasks.

This makes them excellent for cutting soft metals like aluminum and copper, and hard woods, ensuring they are robust enough for both professional and DIY projects. The kit includes blades of various widths (34mm, 45mm, and 65mm), catering to different cutting needs and providing flexibility for various repair jobs, from door frames to window repairs.

The universal interface with three adapters ensures compatibility with most oscillating tools except Starlock systems, making it convenient for users with different tool brands like Dewalt, Dremel, Fein, and Milwaukee. While the blades are cost-effective compared to expensive brand alternatives, they might not fit newer Starlock systems, which could be a drawback for some users. Additionally, the package weight and dimensions are manageable, making storage and handling easy. The warranty and responsive after-sales system also provide reassurance for long-term use. The KELIN blades are a practical choice for those looking to balance affordability and high performance in their metal and wood cutting projects.

Buying Guide for the Best Oscillating Blade For Hard Metal

Choosing the right oscillating blade for cutting hard metal is crucial to ensure efficiency, precision, and durability. Oscillating blades are versatile tools used in various applications, and selecting the right one can make a significant difference in your project outcomes. When picking an oscillating blade for hard metal, consider the following key specifications to ensure you get the best fit for your needs.FAQ

Most Popular Categories Right Now