We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Plywood Cutting Guide 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Plywood Cutting Guide

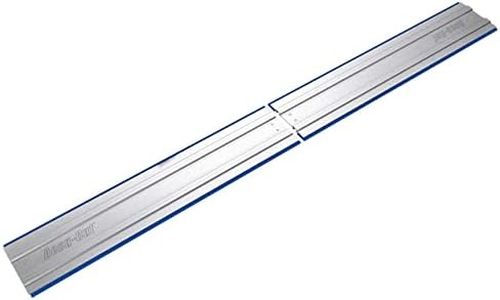

Choosing the right plywood cutting guide can make a significant difference in the quality and precision of your woodworking projects. A good cutting guide helps you make straight, accurate cuts, which is essential for creating professional-looking results. When selecting a plywood cutting guide, consider the following key specifications to ensure you pick the best fit for your needs.LengthThe length of the cutting guide determines the maximum size of the plywood sheet you can cut in one go. This is important because it affects the ease and efficiency of your work. Cutting guides typically come in lengths ranging from 24 inches to 100 inches or more. For smaller projects or if you frequently work with smaller sheets of plywood, a shorter guide may be sufficient. However, if you often handle full-size sheets (4x8 feet), a longer guide will be more practical and save you time by reducing the need for repositioning.

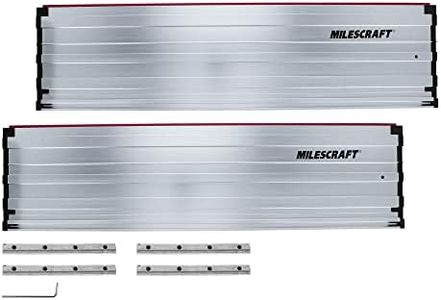

MaterialThe material of the cutting guide affects its durability, weight, and stability. Common materials include aluminum, steel, and plastic. Aluminum guides are lightweight and resistant to rust, making them easy to handle and long-lasting. Steel guides are heavier and more robust, providing excellent stability but can be cumbersome to move around. Plastic guides are lightweight and affordable but may not be as durable or stable as metal options. Choose a material that balances durability and ease of use based on your specific needs and how frequently you plan to use the guide.

CompatibilityCompatibility refers to how well the cutting guide works with your existing tools, such as circular saws or jigsaws. Some guides are designed to be universal, fitting a wide range of saws, while others are brand-specific. Ensuring compatibility is crucial for achieving accurate cuts and avoiding frustration during use. Check the specifications of the cutting guide to see if it matches the make and model of your saw. If you use multiple saws, a universal guide might be the best option for versatility.

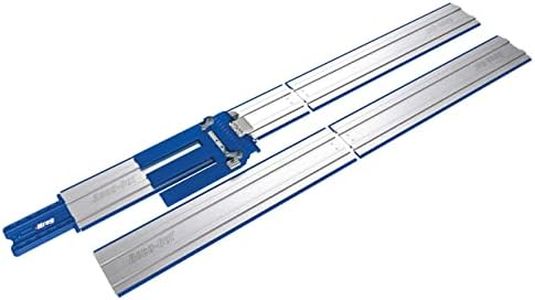

Clamping MechanismThe clamping mechanism is what holds the cutting guide securely in place on the plywood. A reliable clamping system is essential for maintaining straight, precise cuts. There are various types of clamping mechanisms, including screw clamps, quick-release clamps, and suction cups. Screw clamps offer strong, adjustable pressure but can be slower to set up. Quick-release clamps are faster and more convenient but may not provide as much holding power. Suction cups are easy to use but may not work well on rough or uneven surfaces. Consider the type of projects you work on and choose a clamping mechanism that offers the right balance of convenience and stability.

PortabilityPortability refers to how easy it is to transport and store the cutting guide. This is important if you frequently move between job sites or have limited storage space. Some cutting guides are designed to be collapsible or come in multiple sections that can be assembled as needed. Others are rigid and may require more space for storage. If you need to transport your guide often, look for one that is lightweight and easy to disassemble. For stationary use in a workshop, a more robust, single-piece guide might be preferable.

Most Popular Categories Right Now