We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Primer For Rusted Metal 2026 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Primer For Rusted Metal

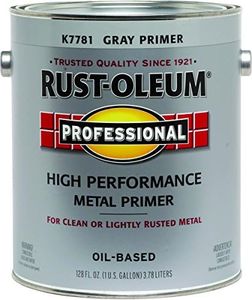

Choosing the right primer for rusted metal is crucial to ensure the longevity and durability of your paint job. A good primer will not only help the paint adhere better but also prevent further rusting and corrosion. When selecting a primer, it's important to consider several key specifications to ensure you get the best product for your needs. Here are the key specs you should focus on and how to navigate them.Rust InhibitorA rust inhibitor is a chemical compound that prevents rust from forming on metal surfaces. This spec is important because it helps to stop the rusting process and protect the metal underneath. Primers with strong rust inhibitors are ideal for heavily rusted surfaces. If your metal is only lightly rusted, a primer with moderate rust-inhibiting properties may suffice. For severe rust, look for primers specifically labeled as 'rust converters' which chemically transform rust into a stable compound.

AdhesionAdhesion refers to how well the primer sticks to the metal surface. Good adhesion is crucial for ensuring that the paint applied over the primer will not peel or flake off. Primers with excellent adhesion are particularly important for smooth or non-porous metals. If your metal surface is rough or heavily rusted, a primer with strong adhesion properties will ensure a more durable finish. For smoother surfaces, a standard adhesion primer may be sufficient.

Drying TimeDrying time is the amount of time it takes for the primer to dry to the touch and be ready for a topcoat. This spec is important because it affects how quickly you can complete your project. Fast-drying primers are ideal if you need to finish your project quickly or if you are working in a time-sensitive environment. However, slower drying primers often provide a more durable and thorough bond. Choose a drying time that fits your project schedule and environmental conditions.

Compatibility with TopcoatCompatibility with the topcoat refers to how well the primer works with the paint you plan to use over it. This is important because some primers are formulated to work best with specific types of paint, such as oil-based or latex paints. Ensure that the primer you choose is compatible with the type of paint you plan to use. If you are unsure, look for primers labeled as 'universal' or 'multi-purpose' which are designed to work with a variety of topcoats.

Corrosion ResistanceCorrosion resistance is the ability of the primer to protect the metal from further corrosion. This spec is crucial for outdoor or marine environments where metal is exposed to harsh conditions. High corrosion resistance is necessary for metals that will be exposed to moisture, salt, or chemicals. For indoor projects or metals that will not be exposed to harsh conditions, a primer with standard corrosion resistance may be adequate.

Ease of ApplicationEase of application refers to how simple it is to apply the primer to the metal surface. This includes factors like the primer's viscosity, whether it can be applied with a brush, roller, or spray, and how well it spreads. A primer that is easy to apply can save you time and effort, especially for large projects. If you are a beginner or working on a complex surface, look for primers that are labeled as 'easy to apply' or 'user-friendly.'

Most Popular Categories Right Now