10 Best Rust Inhibitors 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

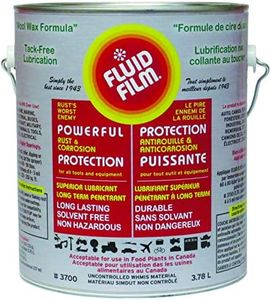

Fluid Film Rust and Corrosion Protection Control Multi Purpose Penetrant and Lubricant (5 Gallon Pail NAS)

Most important from

501 reviews

Fluid Film Rust and Corrosion Protection Control is a lanolin-based rust inhibitor that uses a special wool-wax formula combined with refined oils to protect metal surfaces. It stands out for its long-lasting protection because it doesn't dry out and continues to penetrate into hard-to-reach areas like nuts and bolts, making it excellent for freeing stuck or frozen parts. This makes it very useful in demanding environments like marine, automotive, and industrial settings where corrosion is a big concern.

The product is solvent-free and non-toxic, which is a plus for those worried about environmental impact and safety. However, because it is a thick, waxy liquid, its drying time is quite slow compared to spray or quick-dry rust inhibitors, meaning it stays wet and tacky for a while. This can be a downside if you need faster handling times. Also, while it works on various surfaces including painted metal and plastics, its heavy-duty nature means it can be harder to clean off, so removal isn’t as easy as lighter oils or sprays.

Its use in harsh marine and winter conditions demonstrates its durability under extreme environments. This product is particularly suited for users who need strong, durable rust protection and lubrication in tough environments and are comfortable with a slower drying time and more involved cleanup.

Most important from

501 reviews

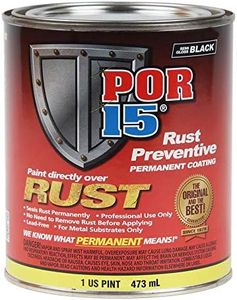

POR-15 Rust Preventive Coating, Stop Rust and Corrosion Permanently, Anti-rust, Non-porous Protective Barrier, 16 Fluid Ounces, Semi-gloss Black

Most important from

5122 reviews

The POR-15 Rust Preventive Coating is highly regarded for its ability to stop rust and corrosion permanently by forming a non-porous, semi-gloss black protective barrier. It is suitable for both interior and exterior use, particularly effective on metal surfaces. A unique feature of this product is its moisture-cured formula, which means it dries faster in the presence of moisture, forming a highly durable and tough finish.

This makes it ideal for automotive, industrial, marine, and construction applications where robust protection against rust and abrasion is necessary. The coating is also resistant to water, chemicals, and salt, making it versatile for different environments. Applying the product requires a specific process, including surface cleaning and preparation with POR-15's own products, and applying a minimum of two thin coats. This method ensures optimal adhesion and performance.

It must be noted that the product needs to be top-coated if it will be exposed to UV light, to prevent degradation. POR-15's commitment to quality and customer service also adds to the reliability of this rust inhibitor. POR-15 Rust Preventive Coating is a strong option for those needing a long-lasting, tough solution to rust and corrosion on metal and other porous surfaces. However, the application process might be more involved compared to other rust inhibitors, and additional top-coating is required for UV protection.

Most important from

5122 reviews

Xion Lab 2-in-1 Rust Converter & Metal Primer - Concentrate Covers Up to 4X More - Industrial Grade Water Based - UV Resistant Rust Reformer & Inhibitor - No Top Coat Needed - Works On Damp Surfaces

Most important from

1284 reviews

The Xion Lab 2-in-1 Rust Converter & Metal Primer is a versatile and efficient solution for treating rust on metal surfaces. One of its standout features is its ability to be applied on damp surfaces, which can save time and effort as it eliminates the need for heavy scraping or sandblasting. The product is water-based, making tool cleanup easy and environmentally friendly with low VOC content and no harmful solvents or resins.

It can cover up to 1000 square feet per gallon, and its durability is impressive, withstanding temperatures up to 300º F for 90 days without cracking or peeling. This makes it suitable for various industrial applications. Another advantage is that it can accept all types of top coatings, or even skip the top coat entirely due to its strong bonding properties. However, the drying and curing time of up to 90 days might be lengthy for some users who need quicker results.

Its water resistance is effective, and the red oxide color provides a metallic finish. The product's weight and size make it manageable for heavy-duty projects. This rust inhibitor is ideal for users who need a robust and flexible solution for exterior metal surfaces, particularly in industrial settings. On the downside, although its performance is commendable, the application on damp surfaces might not be suitable for all types of projects, and the curing time might require users to plan their projects accordingly.

Most important from

1284 reviews

Buying Guide for the Best Rust Inhibitors

Choosing the right rust inhibitor is crucial for protecting metal surfaces from corrosion and extending their lifespan. Rust inhibitors are used in various applications, from automotive maintenance to industrial machinery and household items. To select the best rust inhibitor for your needs, it's important to understand the key specifications and how they relate to your specific use case. Here are the main factors to consider when choosing a rust inhibitor.FAQ

Most Popular Categories Right Now