10 Best Table Saw Blades 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Diablo Ultra Finish Saw Blade for Wood - 10" Diameter, 80 Hi-ATB Teeth, 5/8" Arbor, .098" Kerf, 15� Hook Angle, .071" Plate, 6000 Max RPM - D1080X

The Freud D1080X Diablo 10" 80-tooth ATB Saw Blade is well-suited for those looking for a high-quality blade that delivers ultra-fine finish cuts. With an impressive 10-inch diameter and 80 teeth, this blade is ideal for precise cutting jobs, especially in engineered wood. The ATB (Alternate Top Bevel) tooth configuration enhances cut quality and reduces splintering, making it a great choice for fine woodworking projects.

The carbide material of the blade ensures durability and long-lasting sharpness, which is essential for frequent use. Additionally, the PermaShield coating helps reduce friction and prevent build-up of resin, making the blade easier to maintain and prolonging its lifespan. The laser-cut stabilizer vents are a notable feature as they trap noise and vibration, keeping the blade cool and reducing warping during use.

This can be particularly beneficial for maintaining accuracy and extending the blade's life. The Freud D1080X Diablo blade's ease of use and high performance make it a reliable choice for both amateur and professional woodworkers who need a dependable blade for detailed and smooth cuts.

Diablo Fine Finish Saw Blade for Wood - 10" Diameter, 60 ATB Teeth, 5/8" Arbor, .087" Kerf, 7� Hook Angle, .063" Plate, 6000 Max RPM - D1060S

The Diablo Fine Finish Saw Blade is a 10-inch blade designed to deliver smooth, precise cuts, especially on sliding miter saws, jobsite saws, and workshop table saws. Its 60 teeth with an ATB (Alternate Top Bevel) configuration enable cleaner cuts with minimal tear-out, which is ideal if you work a lot with wood types like oak, pine, or plywood, or do fine finish work such as molding. The blade’s 0.087-inch kerf (the width of the cut it makes) is relatively thin, helping reduce material waste and friction, so your saw uses less power and the cuts are faster.

The 7-degree hook angle helps the blade feed through wood smoothly without grabbing or chipping, making it safer and easier to control. Made with high-density TiCo carbide teeth and a hardened steel body, the blade promises durability and a longer sharp edge life. A special non-stick coating protects it from heat build-up and resin build-up, which can dull blades quickly. However, this blade is optimized for fine finish cuts rather than heavy ripping, so it may not be the best choice if you need to cut large pieces of wood quickly.

Its 5/8-inch arbor fits most standard saws, but you should check your saw’s compatibility before buying. This blade is an excellent option for woodworkers and DIYers who prioritize smooth, accurate cuts and want a blade that stays sharp for longer with less maintenance.

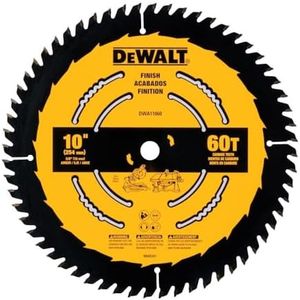

DEWALT 10-inch Miter Saw Blade/Table Saw Blade, 2-Pack, 40T and 60T General Purpose Combo (DWA110CMB)

The DEWALT 10-inch Miter Saw Blade/Table Saw Blade combo pack is designed for both general purpose and precision cutting, making it a versatile choice for hobbyists and professionals alike. With a 40-tooth blade for smoother cuts in softwood and a 60-tooth blade for finer finishes in hardwood, it addresses a wide range of cutting needs effectively. The ultra-sharp carbide material enhances the cutting performance, ensuring clean edges and minimizing tear-out, which is a significant advantage for users looking for quality results.

One of the standout features is the patented body slot design that reduces vibration during operation. Less vibration not only improves accuracy but can also lead to a more comfortable user experience. The optimized tooth geometry is another strength, contributing to better performance and longevity of the blades, which are claimed to last up to three times longer than standard options.

The blades are compatible with various materials, including hardwood, softwood, trim, and sheet goods, making them a practical choice for most woodworking projects. The 10-inch diameter fits many table saws and miter saws, offering good flexibility in use. The DEWALT DWA110CMB combo pack is well-suited for those seeking reliable, high-quality blades for everyday woodworking tasks, balancing performance with durability.

Buying Guide for the Best Table Saw Blades

Choosing the right table saw blade is crucial for achieving the best results in your woodworking projects. The right blade can make a significant difference in the quality of your cuts, the efficiency of your work, and the longevity of your equipment. When selecting a table saw blade, consider the type of material you will be cutting, the type of cuts you need to make, and the precision required for your projects. Here are some key specifications to consider when choosing a table saw blade.FAQ

Most Popular Categories Right Now