10 Best 3D Printers 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

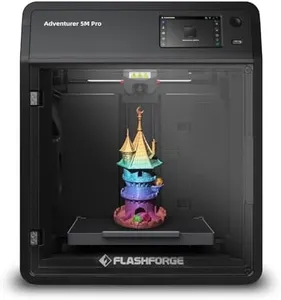

FLASHFORGE Adventurer 5M Pro 3D Printer with 1 Click Auto Printing System, 600mm/s High-Speed, Quick Detachable 280°C Nozzle, Core XY All-Metal Structure, Multi-Functional 220x220x220mm 3D Printer

Most important from

3591 reviews

The FLASHFORGE Adventurer 5M Pro is a well-rounded 3D printer designed to cater to a wide range of users, especially those seeking a balance between speed and quality. It uses Core XY print technology with a sturdy all-metal frame that ensures stability, allowing it to print quickly—up to 600mm per second—without sacrificing detail. The build volume of 220x220x220mm is fairly standard and suits most hobbyist projects or small functional parts.

A standout feature is its ease of use: the printer includes automatic bed leveling with pressure sensing, eliminating the need for manual bed adjustments. This, combined with its quick nozzle heating (up to 200°C in 35 seconds) and a removable dual-sided PEI platform, simplifies setup and post-printing cleanup. The included mobile app provides remote monitoring and control, adding convenience for users who want to keep an eye on prints without being near the machine.

Material compatibility is broad, supporting common filaments like PLA, ABS, and PETG, plus specialty materials including TPU and carbon-fiber infused variants. The nozzle can reach up to 280°C, allowing for these diverse materials. This makes the printer versatile enough for creative projects and more durable prototype parts. The printer weighs over 30 pounds and is moderately sized, requiring some space but not being overly bulky.

This printer is well suited for users who want an easy-to-use, fast, and versatile 3D printer with smart features and good material support. It is particularly beneficial for beginners or intermediate users who value convenience and speed while maintaining good print quality.

Most important from

3591 reviews

Creality K2 Plus Combo 3D Printer, Multi Color Printing with New CFS, Max 600mm/s Printing Speed, Full-auto Leveling, Next-Gen Direct Drive Extruder, Dual Al Camera, Build Volume 350 * 350 * 350mm

The Creality K2 Plus Combo is a versatile 3D printer that stands out with its capacity for multi-color printing and high-speed operation. It supports printing in 16 colors by linking several CFS units, eliminating the need for post-print painting. This is particularly alluring for creative projects that demand a splash of color. Its remarkable print speed, reaching up to 600mm/s, is bolstered by an impressive acceleration capability, making it suitable for quick turnarounds on large projects.

The printer is constructed with a robust build volume of 350x350x350mm, allowing for the creation of larger models. It accommodates a range of materials, including some higher-temperature and carbon-fiber-filled options, thanks to its heated chamber and high-temp nozzle. This flexibility is ideal for users who want to experiment with different materials.

The K2 Plus Combo's ease of use is enhanced by features like full-auto leveling and a strain gauge-based auto-leveling system, which reduce the hassle of manual adjustments. Additionally, dual AI cameras offer real-time monitoring and failure detection, adding a layer of convenience and security. However, at 70.4 pounds, this printer is quite heavy, which may pose a challenge in terms of space and mobility. Its substantial size demands a dedicated setup area, potentially limiting its appeal for users with limited space. Connectivity is focused on compatibility with personal computers, so users with other devices may face limitations.

The Creality K2 Plus Combo is an excellent choice for those needing a versatile, high-performance 3D printer with advanced features, though its size and weight might require some consideration regarding workspace setup.

FLASHFORGE Adventurer 5M 3D Printer with Fully Auto Leveling, Max 600mm/s High Speed Printing, 280°C Direct Extruder with 3S Detachable Nozzle, CoreXY All Metal Structure, Print Size 220x220x220mm

Most important from

3591 reviews

The FLASHFORGE Adventurer 5M 3D Printer offers several appealing features for users looking for a combination of speed, ease of use, and print quality. One of its standout strengths is the fully automatic leveling, which simplifies the setup process and ensures consistent print quality. This is particularly beneficial for those who might not have much experience with 3D printing and want to avoid the hassle of manual adjustments.

The high-speed printing capability (up to 600mm/s) with a sturdy Core XY structure and quick nozzle changes make it an excellent choice for rapid prototyping and mass production. The ability to print with various materials like PLA, ABS, PETG, and TPU adds to its versatility. However, for materials like PC and ASA, an enclosed enclosure is needed, which may require additional investment. The real-time monitoring via the mobile app is a convenient feature, allowing users to keep track of their prints remotely and make adjustments on the fly.

With a decent build volume of 220x220x220mm, it accommodates a good range of project sizes. On the downside, the printer's weight (23.8 pounds) and dimensions make it relatively bulky, which might be a consideration for those with limited space. In essence, the FLASHFORGE Adventurer 5M is well-suited for users seeking high-speed, high-quality prints with minimal manual intervention, making it ideal for both beginners and advanced users in creative and industrial settings.

Most important from

3591 reviews

Buying Guide for the Best 3D Printers

Choosing the right 3D printer can be a game-changer for your projects, whether you're a hobbyist, an educator, or a professional. The key to making the best choice is understanding the various specifications and how they align with your needs. By focusing on the most important specs, you can ensure that you select a 3D printer that will meet your expectations and help you achieve your goals.FAQ

Most Popular Categories Right Now